WhatsApp: +8619037303916

Email: [email protected]

WhatsApp: +8619037303916

Email: [email protected]

Rich In Production

Experience

15 Years Manufacturer Experience.

A Technical Team of 30+ People.

8 production lines

OEM and ODM Accepted.

Rich In Export

Experience

2000+ Cases in Various Industries.

Cranes Are Sold To 50+ Countries

Save Cost On The Package, Transportation, Shipments, Customs Clearance.

Extreme

Service

24h Drawing Provided

48h Price Provided

On-site Service

Branch in Bangladesh, Pakistan, Malaysia, etc

As a leading provider of industrial crane solutions, Kinocranes Crane Parts specializes in manufacturing high-quality OEM overhead crane components, ensuring the smooth operation of your equipment. Our professional team is dedicated to providing reliable and efficient crane solutions, including end truck, crane wheels, crane brakes, gearboxes, gear motors, crane grab buckets, and hooks, etc.

At Kinocranes, we strive to be your one-stop source for all your hoist and crane parts requirements. With our extensive inventory and global supplier network, we can promptly deliver any component – from the smallest seal to a complete hoist. Our commitment to customer satisfaction ensures that you receive the right parts at competitive prices.

Crane Wheel Block

Crane Wheel Block

Kinocranes Wheels are available in a wide range of standard sizes. In addition, crane wheels to meet your special design requirements can be produced in virtually any size, configuration and surface finish condition.

Overhead Crane Brakes

Overhead Crane Brakes

Kinocranes provides a variety of brake options for EOT cranes, including disc, drum, and storm brakes. and have different brake types available to suit different needs and applications.

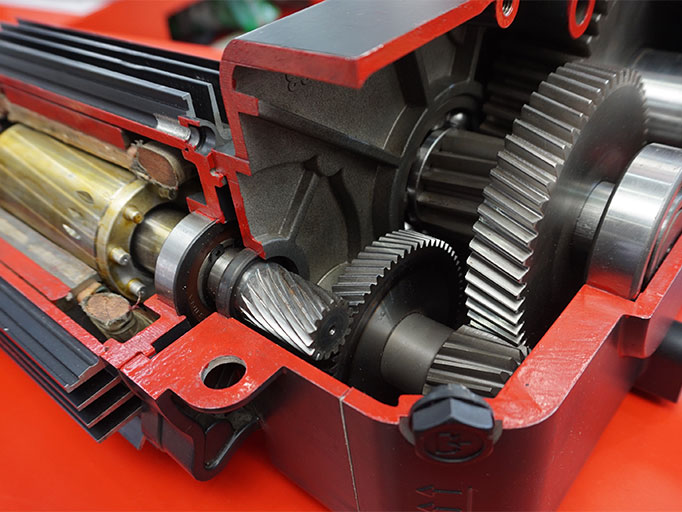

Crane Gearbox

Crane Gearbox

Crane gearboxes are an essential component of crane systems as they help to transfer power from the motor to the crane’s hoist or other lifting mechanisms. A gearbox is a mechanical device that uses gears to increase or decrease the speed and torque of a motor’s output. The gearbox reduces the speed of the motor to increase the torque output, allowing the crane to lift heavier loads.

With close to 15 years of experience, Kinocranes can provide the crane gearbox selection, engineering, and service that you need to withstand the high load and demanding conditions of crane operations

Wire Rope Drum

Wire Rope Drum

Kinocranes has 15 years of experience as a Wire Rope Drums manufacturer in China. which offer competitive pricing and shorter lead times, developed a deep understanding of the wire rope drum market and customer needs

Crane Gear Motor

Crane Gear Motor

Kinocranes lead the way of drive for cranes.You will enjoy silent handling with our crane gear motor.We advocate energy saving with our new technology of drive.

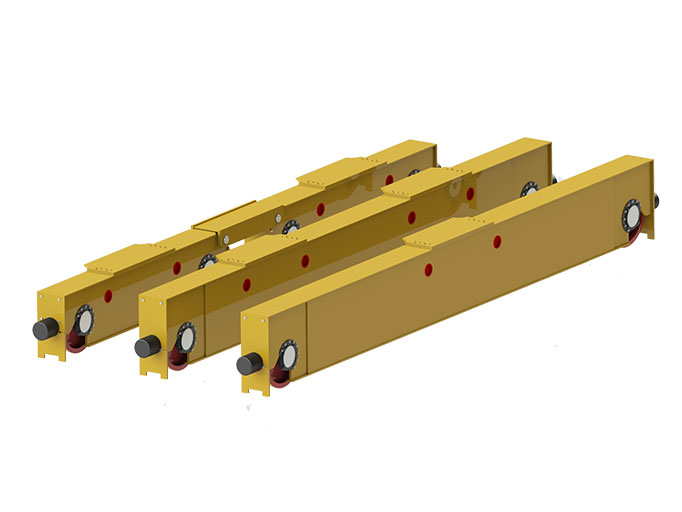

Crane Modular End Carriage

Crane Modular End Carriage

Kinocranes Crane Modular End Carriage have developed in various designs, offer flexibility and high operating reliability.

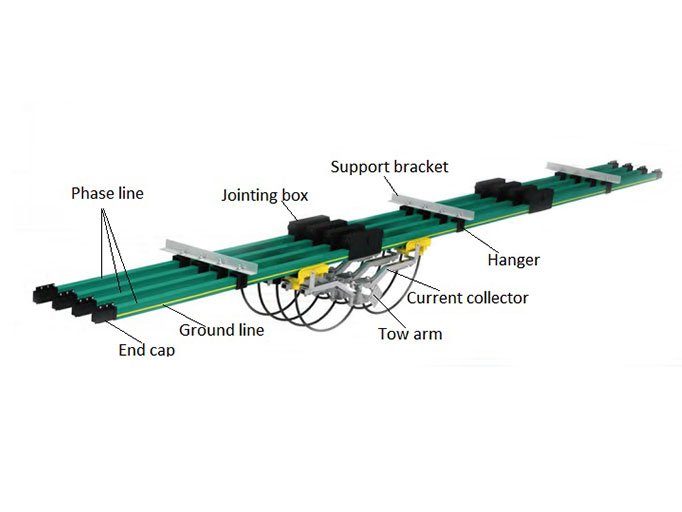

Crane Travel Power Supply Bus Bar System

Crane Travel Power Supply Bus Bar System

Crane busbar is used to supply power to traveling overhead crane. Kinocranes can provide you seamless crane busbar, single pole crane busbar, multipolar busbar, and complete crane busbar system, etc.

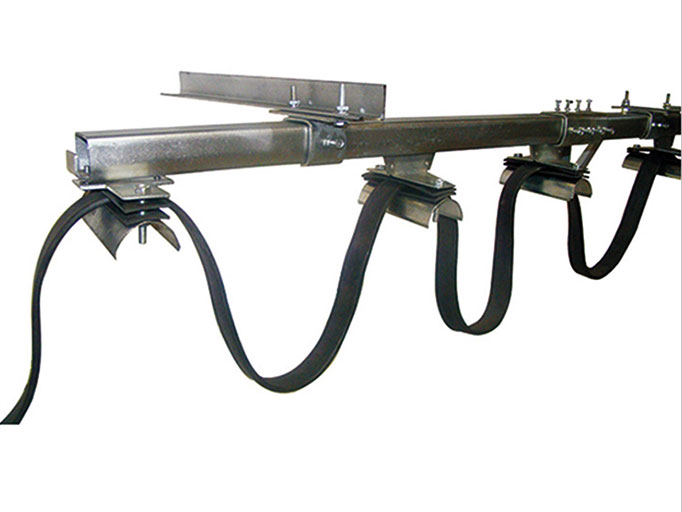

C Track Cable Trolley

C Track Cable Trolley

C Track cable trolley is an ideal logistics power supply system, suitable for indoor and outdoor, dusty and large temperature difference. At present, cable trolley is widely used in all kinds of general bridge crane, gantry crane, electric hoist trolley, warehouse, shipyard, wharf and other lifting equipment of mobile power supply.

Crane Hook Assembly

Crane Hook Assembly

Kinocranes provides various types of crane hooks, with different lifting capacities, from 1 ton, 70 tons, to 500 tons, etc. Kinocranes can design hooks for your unique needs. If you are interested in buying crane hooks, please leave a message.

A Bulgaria customer purchased our crane wheel block, The client is a in tube fabricating industry. These wheels are for their large tonnage overhead cranes for processing the tubes.

A Saudi Arabia customer purchased our 5t double girder overhead crane hoist, The client is in the steel industry. This set of crane electric hoist is going to replace their 10 years old overhead crane lifting mechanism.

The multi-pole power conductor line for crane is a slide line with the function of preventing accidental impact and hazard.

Tech & Manufacture Suppprt

Adaptation to Special Plant Environments

Customized Voltage Supply

Adequate Accessories

Kinocranes know the hazard and challenge of metals production industry. Kinocranes design crane for steel industry with safety first, robust design, high performance advantages.

This kind of manufacturing usually uses a variety of cranes, including High working class, high lifting capacity crane, low working class, low lifting capacity crane.

The entire garbage crane is designed with A8 extra heavy duty according to the actual operating conditions. According to the working environment, humanized design, anti-corrosion design are added and foreign advanced technologies are absorbed and optimized.

TO TOP