WhatsApp: +8619037303916

Email: [email protected]

WhatsApp: +8619037303916

Email: [email protected]

Overhead cranes, also known as bridge cranes, are widely used in various industries for material handling and lifting operations. They consist of parallel runways with a traveling bridge that spans the gap, and a hoist and trolley system that moves along the bridge to lift and transport loads. Overhead cranes are typically classified into two types: single girder and double girder.

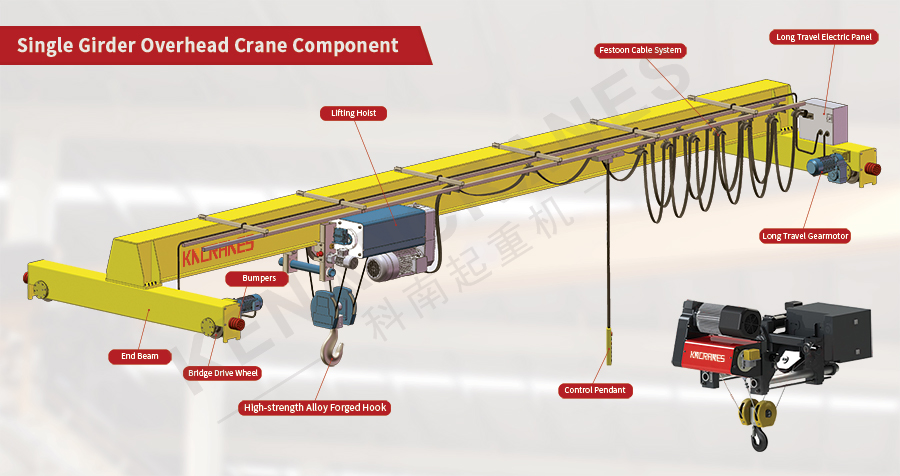

Single Girder Overhead Crane: This type of overhead crane consists of a single bridge girder supported by two end trucks. The hoist and trolley system run along the lower flange of the bridge girder. Single girder overhead cranes are generally more economical and suitable for lighter loads and shorter spans.

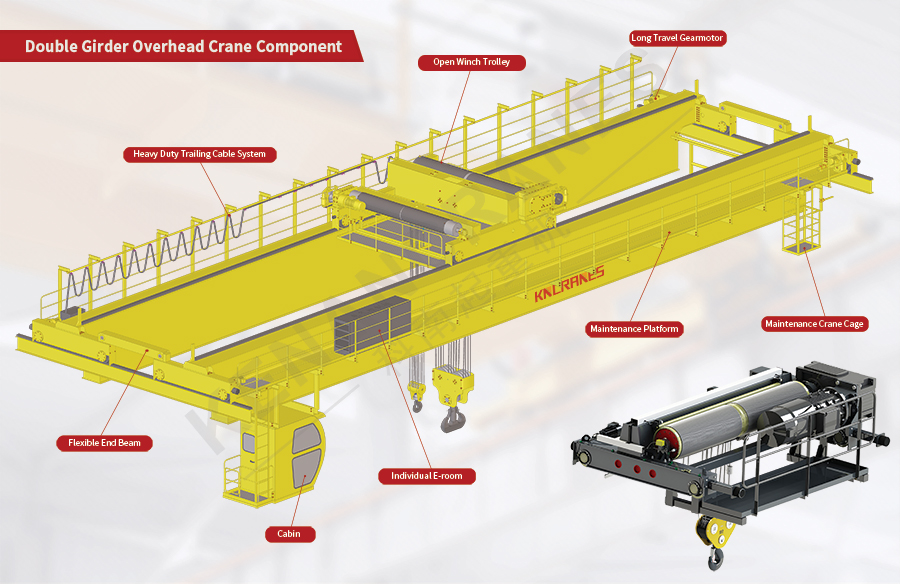

Double Girder Overhead Crane: In a double girder overhead crane, two bridge girders are supported by the end trucks, and the hoist and trolley system runs on rails mounted on top of the girders. Double girder overhead cranes offer greater load capacity, longer spans, and increased hook height compared to single girder cranes. They are ideal for heavier loads and more demanding applications.

Key parts of an overhead crane include:

Parts that are regularly serviced or replaced include:

By regularly servicing and replacing these components, you can ensure the safe and efficient operation of your overhead crane, prolong its service life, and minimize.

Enhance your understanding of overhead crane components with this list and explanation of the most common parts found in any lifting system. Kinocranes extensive product knowledge can benefit you in selecting the right system for your specific needs, ultimately promoting your business profits.

Let Us Help You Select The Right System For Your Job

Kinocrane is a leading manufacturer that specializes in providing customized overhead crane solutions and general crane components. In order to offer cost-effective and flexible lifting solutions, Kinocrane has developed innovative strategies that minimize transportation costs while maintaining robust and reliable designs.

One such approach is the use of end beams that can be sectioned for transport and later bolted together securely on-site. This design not only ensures a sturdy structure but also significantly reduces shipping costs, making it an attractive option for businesses looking to optimize their investments.

Kinocrane offers a unique and cost-effective solution for its clients by providing the necessary drawings and technical guidance for the local fabrication of the main girder. This approach allows clients to produce the main girder on-site, reducing transportation costs and streamlining the overall process. For the remaining crane components, Kinocrane takes care of the production and ships them directly to the client's location. This comprehensive support ensures a seamless and efficient assembly process, tailored to the specific needs of each client. By combining local fabrication of the main girder with the delivery of high-quality components from Kinocrane, clients can achieve significant cost savings without compromising the performance or reliability of their overhead crane systems. This innovative approach makes Kinocrane a preferred partner for businesses seeking customizable and cost-effective lifting solutions.

With their expertise in the field and commitment to customer satisfaction, Kinocrane is a valuable partner for businesses seeking high-quality, customizable, and cost-effective overhead crane solutions. Their innovative designs, extensive product range, and technical know-how make them a trusted choice for various industries around the world.

More Detailed information about overhead cranes or any types of cranes you are in need of your business, be free to contact us.

TO TOP