Description

The Electric Tilting Coil Tong, also known as Coil Tippers, is an exceptional lifting apparatus.This product finds widespread utility in scenarios where vertical coils need to be lifted and flipped into horizontal positions, or horizontally placed coils require flipping into a vertical orientation. It is particularly suited for streamlining vehicle loading and unloading tasks, offering convenience and efficiency. Additionally, it is well-suited for specialized lifting operations involving vertically or horizontally oriented coils. The Electric Tilting Coil Tong’s outstanding performance ensures it is an ideal choice for efficient, safe, and precise handling in various applications.

The tongs for aerial coil tilting consists of the lifting ear section, tilting section, tong section, chain, electrical components, and button station.

Key Component Parameters

- The brand (Delixi, SEW) electrical components ensure top-notch reliability.

- Tilting gearbox and clamping motor from a leading Chinese brand, ensuring superior performance.

- The tilting double-plate heavy-duty chain, with a safety factor of 3, is forged from robust 40Mn material, guaranteeing reliability.

- Crafted with finesse, the steel plate is Q355B, and the tong mouth is forged using cutting-edge techniques.

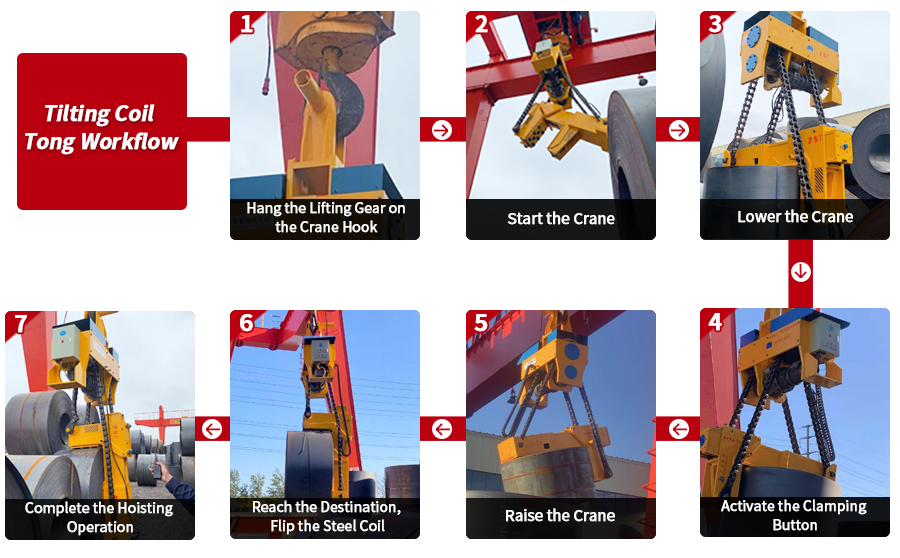

Tilting Coil Tong Workflow

- Hang the Lifting Gear on the Crane Hook: Lower the crane hook into the lifting ear of the tilting coil tong, insert it into the lifting ear of the tilting coil tong.

- Start the Crane: Activate the crane to lift the electric tilting coil tong above the vertically suspended steel coil.

- Lower the Crane: Descend the crane, lower the legs of the electric steel coil tilting coil tong into the inner hole of the suspended steel coil.

- Activate the Clamping Button: Start the clamping button of the electric steel coil tilting device, tighten the outer legs of the clamp to secure the steel coil.

- Raise the Crane: Lift the crane, raising the clamp with the steel coil away from its original position.

- Reach the Destination, Flip the Steel Coil: Upon reaching the destination, lower the crane, simultaneously activate the flipping button to rotate the steel coil 90 degrees during the movement.

- Complete the Hoisting Operation: After completing the flipping process, operate the crane to move the tilting coil tong away from the steel coil, concluding a single hoisting and flipping operation.