WhatsApp: +8619037303916

Email: [email protected]

WhatsApp: +8619037303916

Email: [email protected]

Overhead bridge cranes are essential equipment in various industries, providing efficient and safe handling of heavy loads. Among the different types of overhead cranes, top running and under-hung bridge cranes stand out due to their versatile applications and advantages. This article will discuss these two types of bridge cranes, their components, how to choose the right one for your facility, and essential safety tips.

Types of Bridge Cranes

Top Running Bridge Cranes

Top Running Bridge Crane Advantages

Top running bridge cranes are the most common type of overhead crane, known for their robust construction and high load capacities. They run on rails mounted on top of the runway beams, allowing for excellent stability and long spans. This design enables them to handle heavy loads, making them ideal for heavy industries such as steel, automotive, and shipbuilding.

Top Running Bridge Crane Applications

Top running bridge cranes are widely used in various industries where heavy lifting is required. Their applications range from transporting raw materials, moving machinery, and assisting in assembly lines to loading and unloading heavy items in warehouses.

Under-Hung Bridge Cranes

Under-Hung Bridge Crane Advantages

Under-hung bridge cranes, also known as under-running cranes, run on rails attached to the bottom flanges of the runway beams. They offer several advantages, including lower headroom requirements and more accessible installation compared to top running bridge cranes. Due to their flexible design, they can be easily integrated into existing building structures, making them an ideal choice for facilities with limited space.

Under-Hung Bridge Crane Applications

Under-hung bridge cranes are commonly used in light to medium-duty applications. They are suitable for use in manufacturing, automotive assembly, warehousing, and maintenance tasks, among other applications.

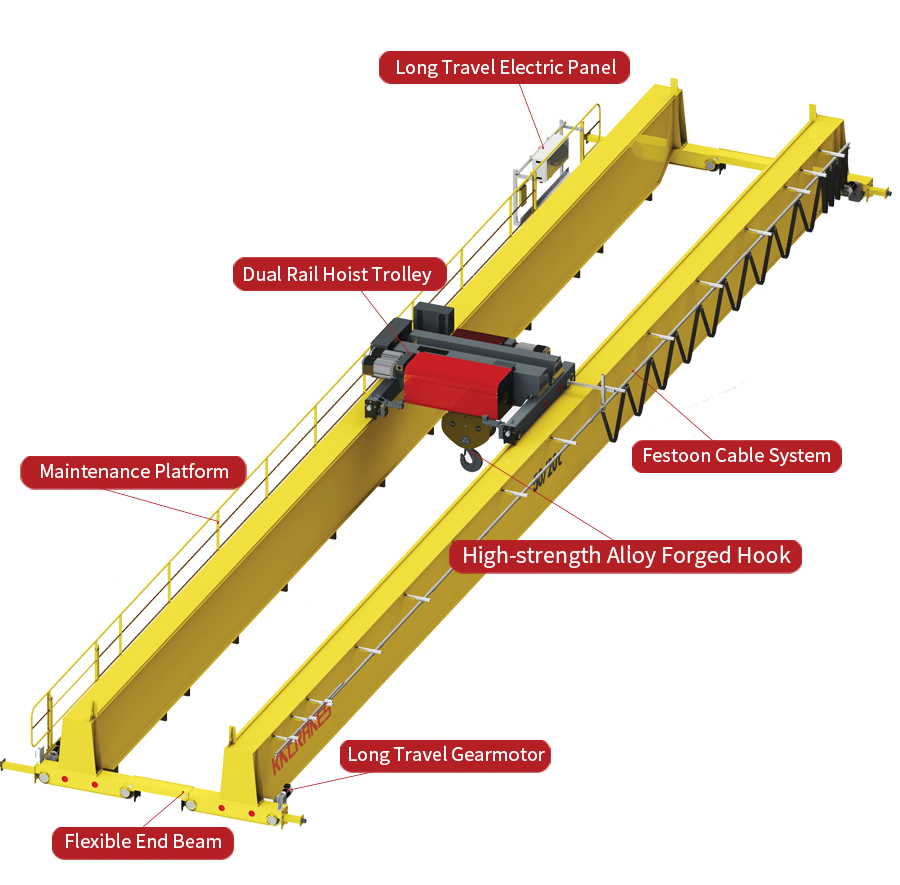

Key Components

Bridge Girder

The bridge girder is the primary horizontal beam that spans the width of the crane, supporting the hoist and trolley. In top running bridge cranes, the bridge girder runs on rails mounted on top of the runway beams, while under-hung cranes have rails attached to the bottom flanges.

End Trucks

End trucks are located at both ends of the bridge girder, connecting it to the runway beams. They house the wheels and drive mechanism that propel the crane along the runway.

Hoist and Trolley

The hoist and trolley system lifts and moves the load. The hoist lifts the load vertically, while the trolley travels horizontally along the bridge girder. The combination of these movements enables precise positioning of the load in the workspace.

Controls

Crane controls can be either wired or wireless, allowing operators to control the movement of the crane, hoist, and trolley. Operators can use a pendant, remote control, or a control station located in a cabin attached to the crane.

Power Supply

Bridge cranes are typically powered by electricity, either through a direct connection or a conductor bar system. The power supply ensures smooth and continuous operation of the crane's movements and functions.

Choosing the Right Crane

Capacity

When selecting a bridge crane, consider the maximum weight of the loads you will be handling. Top running bridge cranes are ideal for heavy lifting tasks, while under-hung cranes are more suitable for light to medium-duty applications.

Span and Lift Height

The span is the distance between the runway beams, while the lift height is the maximum vertical distance the hoist can lift a load. Choose a crane with a span and lift height that can accommodate your facility's requirements.

Environment

Consider the environment in which the crane will operate. Factors such as temperature, humidity, and exposure to corrosive substances can affect the crane's performance and durability. Make sure to select a crane designed to withstand your facility's environmental conditions.

Installation and Maintenance

Top running bridge cranes typically require more extensive installation processes, while under-hung cranes are easier to install. Consider the ease of installation and the ongoing maintenance requirements of the crane to ensure efficient operation and minimal downtime.

Safety Tips

Operator Training

Ensure that crane operators receive proper training and certification to operate the crane safely and efficiently.

Inspection and Maintenance

Regular inspections and maintenance are crucial to ensure the crane's safe and reliable operation. Follow the manufacturer's guidelines for inspection and maintenance schedules.

Proper Use

Always operate the crane according to the manufacturer's guidelines and capacity limits. Overloading or improper use of the crane can result in accidents and damage to the equipment.

Conclusion

Top running and under-hung bridge cranes are versatile and valuable pieces of equipment for various industries. Understanding their differences, components, and how to choose the right one for your facility can help you optimize productivity and safety. Implementing essential safety practices will ensure the long-term, efficient operation of your crane.

FAQs

Are you ready to optimize your facility with the perfect bridge crane solution? Our team of experts is here to help you select and install the ideal crane for your specific needs. Don't hesitate to contact us today for a free consultation and let's work together to enhance your productivity and safety.

TO TOP