WhatsApp: +8619037303916

Email: [email protected]

WhatsApp: +8619037303916

Email: [email protected]

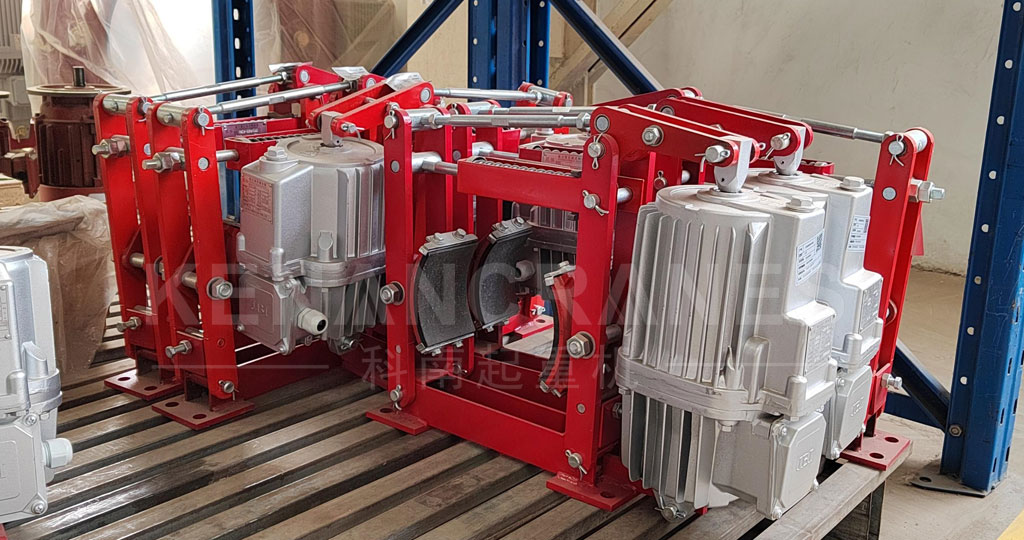

Overhead crane brakes play a crucial role in ensuring safe and efficient operations in industrial settings. In this blog post, we'll explore the different types of crane brakes and how they work to prevent accidents and ensure optimal performance.

A. Disc brakes

B. Shoe brakes

C. Magnetic brakes

D. Hydraulic brakes

A. Importance of regular maintenance and inspections

B. Safety considerations

Overall, understanding how overhead crane brakes work is essential for ensuring safe and efficient operations in industrial settings. By choosing the right type of brake and following proper maintenance and safety procedures, companies can help prevent accidents and ensure optimal performance.

TO TOP