WhatsApp: +8619037303916

Email: [email protected]

WhatsApp: +8619037303916

Email: [email protected]

Simple overview:

Specific method:

(1) According to the rail model proposed by the process, select the corresponding crane track rail climps model.

| Rail Model | Crane Rail Climps Model | Rail Model | Crane Rail Climps Model |

| TG38 | WJK-TG38 | QU70 | WJK-QU70 |

| TG43 | WJK-TG43 | QU80 | WJK-QU80 |

| TG50 | WJK-TG50 | QU100 | WJK-QU100 |

| TG60 | WJK-TG60 | QU120 | WJK-QU120 |

(2) The base plate of the crane rail climps are welded with the crane beam, and the selection of the electrode type should be compatible with the material of the connecting piece. For example, when using Q325 or Q345 steel, use E4315 or E5015 electrodes respectively.

The intermediate working crane adopts the welding seam on both sides. Heavy-duty (extra-heavy) working cranes use three-sided surrounding welds.

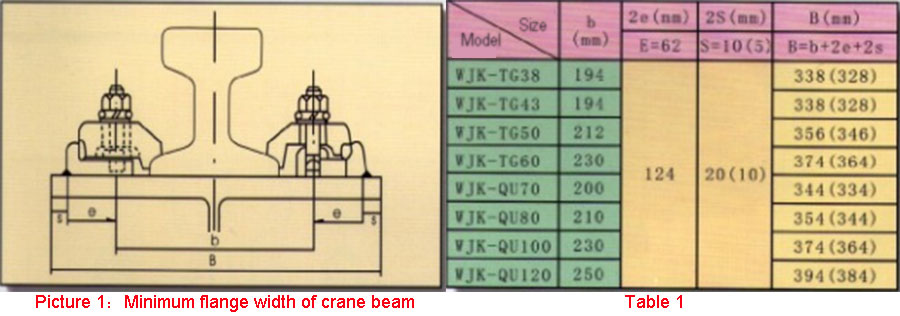

(3) The minimum width of the upper flange of the crane girder required for the connection of the rail by the crane track rail climps is shown in Picture 1: the “b” value in the figure is found in Table 1.

Note: In Table 1, (a) The dimensions in parentheses in the table are only the minimum width of the upper flange of the weld on both sides of the base.

(b) The B value does not include the dimensions associated with the crane girder braking system.

(4) Distance "a" from the center of the T-bolt of the crane track rail climps to the center of the rail.

| Crane Rail Climps Model | a(mm) |

| WJK-TG38 | 97 |

| WJK-TG43 | 97 |

| WJK-TG50 | 106 |

| WJK-TG60 | 115 |

| WJK-QU70 | 100 |

| WJK-QU80 | 105 |

| WJK-QU100 | 115 |

| WJK-QU120 | 125 |

(5) Base plate positioning. The base plate is arranged at a distance of 600mm or 500mm along the direction of the crane rail; the vertical rail direction is positioned according to the value “a” between the center of the T-bolt and the center of the rail.

(6) Welding base plate

(7) Assemble the crane track rail climps in the following order:

The T-bolt is in place → the adjustment plate, the upper cover plate → the flat washer → the spring washer → the nut → the T-bolt is tightened → the adjustment plate is adjusted as a whole → the T-bolt is finally tightened.

(8) T-bolts are installed and tightened, and the spring washer is finally pressed until the height difference at the joint is 2mm.

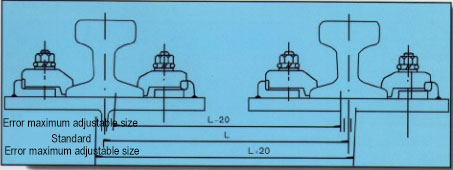

(9) The maximum adjustable size of the gauge is shown in the figure below.

(1) The WJK type crane track rail climps’ base plate is welded with the upper flange plate of the steel crane girder by three-sided surrounding welding or two-sided side welding, which can ensure that the lateral force of the crane is smoothly and evenly transmitted to the crane girder. Moreover, the defect of weakening the flange section caused by a large number of openings in the flange of the crane beam is avoided. Therefore, the section strength and bearing capacity of the crane beam are effectively improved.

(2) The WJK type crane track rail climps’ base plate and the lower end of the T-bolt form a spherical hinge connection. Therefore, under the action of lateral force, the T-bolt is kept perpendicular to the upper cover plate, and deflection is allowed. It can reduce the damage of the lateral impact force of the crane to the rail, crane beam and braking system and other structures. Thereby extending the service life of the structure.

(3) The WJK type crane track rail climps are equipped with a gauge adjustment plate for adjusting the gauge. It can improve the installation accuracy and reduce the unevenness deviation of the rail centerline. It has a two-way self-locking function to prevent loosening during use.

(4) The WJK type crane track rail climps’ bolts and the upper cover plates are free to disassemble and assemble, which provides extremely convenient conditions for construction, installation and maintenance.

(5) The WJK type crane track rail climps’ upper cover plate is consistent with the curvature of the rail section, which can not only compress the rail, but also does not prevent the rail from sliding slightly in the longitudinal direction.

(6) There are two materials for the base plate of the WJK type crane track rail climps:

① ZG270-500 material, the bolt is C grade, the tightening torque is 150N.m, and the maximum lateral force acting on each wheel pressure is 45KN;

② ZG16Mn material, bolts are grade 8.8, the tightening torque is 220N.m, and the maximum lateral force at each wheel pressure is 55KN.

WJK crane track rail climps material should be specified when ordering to prevent the effect.

(7) Crane beam structure: WJK type crane track rail climps are mainly used for steel crane beam rail fixation, and can also be used for the transformation of old concrete crane beams and track rail transformation of ground transportation equipment.

TO TOP