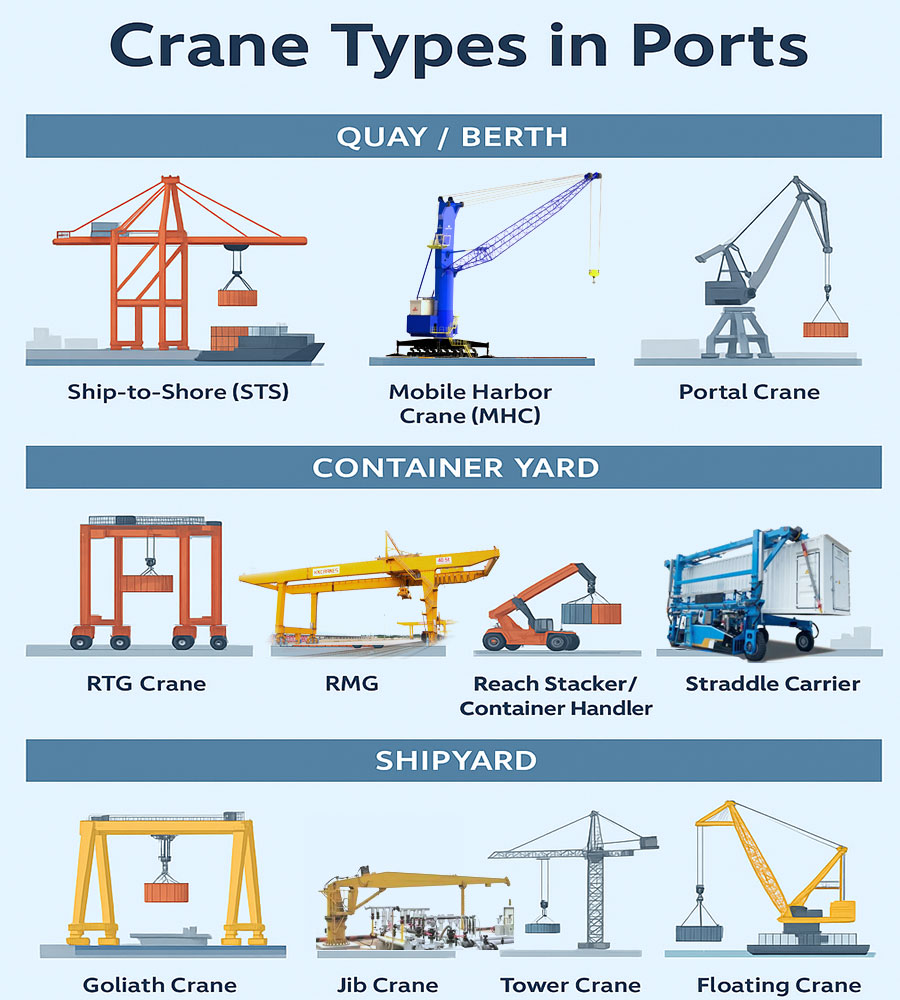

Ports and terminals are among the most complex logistics systems in the world. Their efficiency depends heavily on the cranes that move containers, bulk cargo, and heavy ship components between ships, trucks, and yards.

Container cranes, including quay cranes and yard cranes, play a vital role in the efficiency and effectiveness of port and harbor operations. Recent studies emphasize the importance of integrated scheduling and equipment selection to optimize container handling processes while considering environmental impacts.

Container cranes are the backbone of every container terminal. They include ship-to-shore (STS) cranes for vessel operations and yard cranes for stacking and storage.

| Type | Description | Typical Use |

|---|---|---|

| STS Crane (Ship-to-Shore Crane) | Large gantry crane fixed on the quay; transfers containers between ship and dock. | Container terminals |

| RTG Crane (Rubber Tyred Gantry Crane) | Mobile gantry crane on rubber tires; stacks containers in the yard. | Container yards |

| RMG Crane (Rail Mounted Gantry Crane) | Similar to RTG but runs on rails; higher capacity and stability. | Container terminals, intermodal yards |

| Straddle Carrier | Self-propelled vehicle that lifts and carries containers short distances. | Container yards |

| Reach Stacker / Container Handler | Wheeled vehicle with telescopic boom for stacking and moving containers. | Container yards, depots |

Joint scheduling efficiency:

The integrated scheduling of quay cranes, yard cranes, and trucks is crucial for optimizing terminal operations. Studies such as Hsu et al. (2021) highlight that heuristic methods like the Multiple Groups Particle Swarm Optimization (MGPSO) outperform conventional scheduling algorithms in minimizing idle time and enhancing throughput.

Environmental considerations:

Sustainability is increasingly influencing port operations. Gan et al. (2021) identify rubber-tyred gantry cranes as the most environmentally friendly solution, combining efficiency with reduced carbon emissions — a direction supported by Kino Cranes’ RTG technology for green ports.

Shipyard cranes are purpose-built for the assembly, maintenance, and repair of large ships and offshore structures.

Common types include:

| Type | Description | Typical Use |

|---|---|---|

| Goliath Crane (Gantry Crane) | Massive gantry spanning dry docks; lifts ship sections and blocks. | Shipbuilding docks |

| Jib Crane | Fixed or mobile crane with a horizontal jib; used for smaller parts and tools. | Workshops, ship assembly lines |

| Tower Crane | Tall crane used for assembling ship superstructures or buildings. | Ship assembly areas |

| Floating Crane / Crane Barge | Mounted on a barge; can lift heavy components on water. | Offshore or dockside lifting |

Shipyards rely on high-capacity cranes with synchronized lifting systems to ensure precision and safety when positioning massive ship sections.

Beyond containerized cargo, ports handle millions of tons of bulk materials, project cargo, and general freight every year.

Cargo cranes must combine power with flexibility to manage these diverse loads.

Typical models include:

| Type | Description | Typical Use |

|---|---|---|

| Portal Crane / Level Luffing Crane | Rail-mounted crane with a long horizontal jib that moves cargo without changing hook level. | Bulk terminals, general cargo docks |

| Mobile Harbor Crane (MHC) | Wheeled crane, flexible and mobile; handles containers, bulk, and project cargo. | Multipurpose ports |

| Fixed Slewing Crane | Fixed base crane that rotates to load/unload general or bulk cargo. | Small harbors, piers |

| Grab Crane | Equipped with grab bucket for bulk materials (coal, sand, grain). | Bulk cargo terminals |

| Floating Crane | Used for oversized or heavy cargo that cannot be handled from shore. | Offshore operations, salvage work |

These cranes ensure smooth handling operations in multipurpose terminals, bulk cargo ports, and logistics hubs.

Modern crane design focuses on:

Kino Cranes continuously integrates these innovations, ensuring compatibility with global port modernization and environmental goals.

The efficient coordination of container, shipyard, and cargo cranes determines the overall performance of modern ports and terminals.

Through advanced engineering and automation, Kino Cranes provides solutions that align with global research insights — enhancing efficiency, sustainability, and productivity across the maritime logistics chain.

| Area | Common Cranes Used |

|---|---|

| Quay / Berth | STS, MHC, Portal Crane, Fixed Slewing Crane |

| Container Yard | RTG, RMG, Reach Stacker, Straddle Carrier |

| Shipyard | Goliath Crane, Jib Crane, Tower Crane, Floating Crane |

| Bulk / Cargo Terminal | Grab Crane, Portal Crane, Mobile Harbor Crane |

Selecting the right crane is crucial to ensuring efficiency, safety, and cost-effectiveness in port and shipyard operations. Whether you're handling containers, heavy cargo, or large ships, understanding the unique requirements of your operations will guide you in making the best choice. Here are key factors to consider when choosing the ideal crane for your needs:

The first step in choosing a crane is understanding the nature of the cargo and the frequency of its handling. Different types of cranes are suited for specific tasks:

The lifting capacity and reach of a crane will largely determine whether it can handle the required loads and fit into the operational environment:

Evaluate the available space for crane installation. Port or shipyard layout, the size of the vessels or cargo, and the overall infrastructure are key factors:

Modern cranes are increasingly integrated with automation and smart technology to improve efficiency, reduce human error, and enhance safety:

Safety is a critical consideration when choosing a crane, especially in high-traffic areas like ports and shipyards. Look for cranes with advanced safety features, such as:

While the initial purchase cost is an important factor, long-term costs such as maintenance, energy consumption, and downtime should also be considered:

Investing in cranes that are adaptable to future technological advancements is a smart choice for growing businesses. Look for cranes that are:

Finally, it is always a good idea to consult with experts in the field of material handling and crane technology. Manufacturers and suppliers can offer valuable insights into which cranes are best suited to your specific operations. Additionally, they can provide guidance on factors like installation, customization, and after-sales support.

| Crane Type | Selection Criteria | Advantages | Disadvantages | Applicable Scenarios |

|---|---|---|---|---|

| Container Cranes | ||||

| Portal Cranes | - Limited port space - Need for flexibility to cover multiple operational areas | - High flexibility, suitable for confined spaces - Smaller footprint, adaptable to different cargo handling operations | - Lower lifting capacity and reach compared to quay cranes | - Small to medium ports - Confined or constrained operational environments |

STS Crane (Ship-to-Shore) | Large-scale ship-to-port container handling | Large ports with high container traffic | High lifting capacity, long reach, efficient loading | Requires large space, high cost |

RTG Crane (Rubber Tyred Gantry) | Yard handling with flexibility | Medium-sized ports, smaller terminal operations | Highly mobile, suitable for tight spaces, electric models available | Slower speed, limited reach compared to STS cranes |

RMG Crane (Rail Mounted Gantry) | Fixed-rail operations for container stacking | Rail-connected terminals, large container yards | High precision, large reach, efficient in structured layouts | Fixed path, requires rail infrastructure |

Straddle Carrier | Self-propelled mobile container handler | Small to medium ports, confined space operations | Highly flexible, easy to deploy, no rail required | Lower load capacity, limited reach |

Reach Stacker | Mobile and compact container handler | Smaller ports, inland logistics, or warehouse use | Flexible, cost-effective, easy to maneuver | Lower lifting capacity, slower speed |

| Shipyard Cranes | ||||

| Gantry Cranes | - Need for wide span and high lifting capacity - Shipyard layout requirements | - High lifting capacity - Ideal for handling large ship components - Can move freely within the shipyard | - Requires large space, suitable for large shipyards - High cost | - Large shipyards - Large-scale shipbuilding and deconstruction |

| Ship Cranes | - Need for precise lifting of ship components and equipment - Regular maintenance or deconstruction of ships | - High precision for ship installation and repair - Highly flexible, suitable for ship deconstruction and maintenance | - Lower lifting capacity, not suitable for very large ships | - Ship repairs - Ship deconstruction and regular maintenance |

| Cargo Cranes | ||||

| Fixed Cranes | - Primarily handling one type of cargo - Frequent and continuous operation | - Lower cost - Efficient for handling a single type of cargo - Stable operation | - Not suitable for multi-point operations - Lack of flexibility | - Single cargo type - Frequent, repetitive operations |

| Mobile Cranes | - Need to operate across multiple areas - Non-fixed work environment | - Highly flexible, can move between various work areas - Ideal for tight spaces | - Lower operational efficiency compared to fixed cranes - Requires regular maintenance | - Multiple work points - Tight spaces or environments requiring frequent relocation |

| Heavy Duty Cranes | ||||

| Heavy Duty Cranes | - Handling super heavy cargo - Specialized industrial or offshore engineering needs | - Extremely high lifting capacity for heavy cargo - Highly stable, suitable for specialized environments like offshore platforms | - High cost - Requires specialized training for operation - Stringent safety requirements | - Super heavy cargo handling - Offshore engineering - Heavy industrial equipment installation and maintenance |

Selecting the right crane requires a comprehensive understanding of your operational needs, space constraints, lifting requirements, and future growth potential. By considering factors like crane capacity, automation, safety features, and environmental durability, you can make an informed decision that will improve your operational efficiency, reduce costs, and enhance safety.

Whether you're in a port, shipyard, or warehouse, the right crane can streamline your operations and give you a competitive edge in today’s fast-paced logistics industry.

TO TOP