A crane sheave is a key load-bearing and rope-guiding part in the hoisting mechanism. Its actual working condition directly affects lifting safety, wire rope service life, and the overall reliability of the equipment. This technical guide explains the design principles for sheave shaft stiffness, and lays out clear operational criteria for sheave replacement.

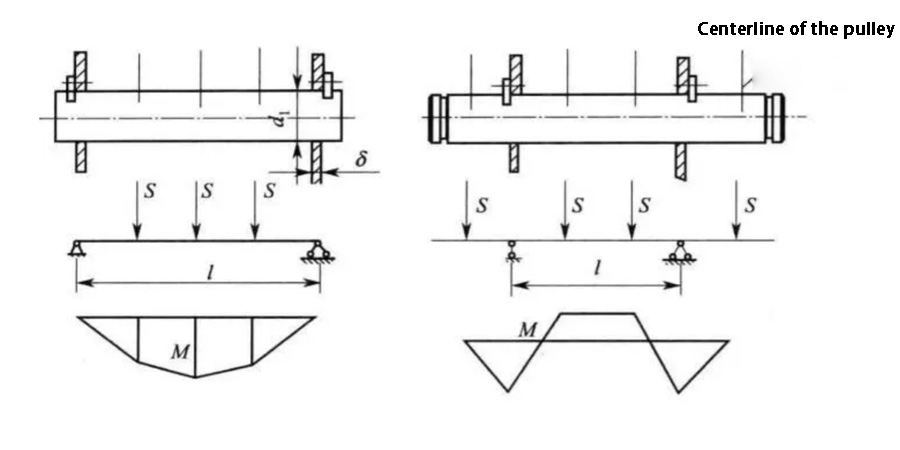

In most overhead crane designs, the sheave shaft functions as a stationary axle or mandrel. Its primary role is to withstand bending moments from rope forces rather than to transmit torque. Its design focuses on two critical aspects: bending strength and, where applicable, stiffness.

The shaft must possess sufficient strength to resist bending stresses under load without yielding or failing in fatigue. The fundamental bending stress calculation is:

σ = M / W ≤ [σ]

Where:

Although shaft structural failure is mostly controlled by stress, excessive deflection caused by insufficient stiffness can still create a range of secondary problems.

Common issues include:

A stiffness check is therefore necessary if deflection is likely to affect functional performance.

A standard preliminary rule limits the maximum shaft deflection to 0.0003 times the bearing span.

Permissible angular misalignment at the bearing seats is also defined and depends on the bearing type:

For long rotating shafts operating at high speeds (usually over 400 RPM), a dynamic analysis is essential to avoid resonance. The working speed must stay safely below the shaft’s first critical speed, so as to prevent destructive vibration.

Key Takeaway:

For a standard crane sheave shaft, strength (both static and fatigue) is the primary design driver. Stiffness is evaluated to ensure it does not become a limiting factor for associated components. The final shaft dimensions are often dictated by the selected bearing's load capacity and the required fatigue life, with stiffness serving as a verification check.

Regular, detailed inspection of sheaves is essential for preventive maintenance. A sheave must be immediately removed from operation and replaced upon meeting any of the following conditions:

Adherence to the stiffness and strength principles in shaft design during manufacturing, coupled with rigorous enforcement of the replacement criteria during operation, is fundamental to a safe and reliable crane hoisting system. Proactive monitoring and timely replacement of worn crane sheaves prevent unexpected downtime, protect the more costly wire rope, and mitigate safety risks. For durable replacement crane components engineered to these standards, explore our product offerings.

TO TOP