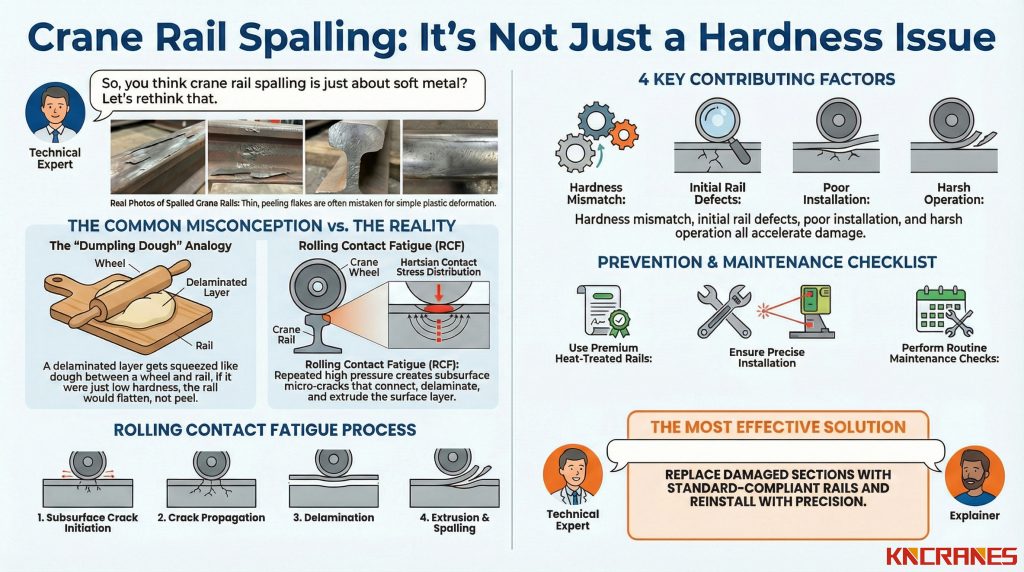

As shown in the images above, this is a typical example of crane rail tread spalling—characterized by thin, flaky, iron-sheet-like peeling on the rail surface.

Common wheel-rail interaction issues in overhead cranes include rail leaning (uneven contact due to misalignment), rubbing (minor friction), and the more prevalent gnawing (severe side wear from lateral forces). However, the case presented here is relatively rare: thin-sheet-like extrusion and peeling specifically on the rail tread.

At first glance, it may seem caused by insufficient rail hardness, leading to plastic deformation and material squeeze-out from repeated wheel rolling. But this cannot be explained solely by low hardness and plastic deformation—for instance, pure plastic deformation would primarily result in overall rail flattening or depression, rather than the observed thin, flaky extrusion.

This type of surface-layer extrusion peeling is not due to a single cause. Let's analyze it step by step to uncover the true mechanisms.

This thin-sheet extrusion peeling results from repeated wheel rolling, where cyclic contact stresses cause micro-cracks to initiate on the rail surface and propagate to a certain subsurface depth. This creates a delaminated layer at a specific thickness on the tread, separated from the main rail body but not fully detached.

This delaminated layer is akin to dumpling wrapper dough: trapped between the "rolling pin" (the crane wheel) and the "cutting board" (the solid rail base), it is repeatedly rolled thinner and squeezed. Due to slight angular misalignment between the wheel and rail tread, the extruded material always extends toward the side of least resistance, forming the iron-skin-like surface flakes we observe.

The fundamental reason is rolling contact fatigue (RCF) combined with concentrated shear stress. The wheel-rail contact has the following characteristics:

Under repeated rolling, these regions experience stress accumulation, microscopic plastic deformation, dislocation movement, slip plane intersections, and ultimately micro-crack formation.

Several factors may contribute to this phenomenon:

The simplest and most effective approach is to replace the damaged rail sections with material and performance that meet standards, followed by precise reinstallation and alignment.

As an integrated overhead crane manufacturer focused on export-quality products, we prioritize durable wheel-rail systems in our designs to prevent such issues. Explore our overhead crane series for reliable, long-life solutions—including full support from design to installation. Contact us for professional guidance!

TO TOP