The Wire Rope on a Gantry Crane is a critical component that handles the heavy lifting load. Its service life and replacement cycle are key to the safe operation of any Gantry Crane. In the following discussion, we will cover aspects such as the determinants of the service life, the inspection and maintenance of the wire rope, and the replacement cycle.

A gantry crane’s wire rope service life hinges on several key operational factors, the main ones as follows:

1. Load factors

Static loads act on the rope when heavy objects are suspended or stationary, while dynamic loads come from lifting, moving and stopping operations. Sustained operation near the rope’s rated capacity speeds up metal fatigue and wear.

2. Working environment

Extreme temps, humidity and corrosive conditions all affect wire rope service life. Humid, corrosive environments in particular cause rope corrosion and shorten its lifespan.

3. Maintenance

Regular inspection, cleaning, lubrication and maintenance of the steel wire rope can help extend its service life. Proper handling of issues such as wear, broken wires and corrosion of the steel wire rope can reduce the consumption of its lifespan.

A proactive approach to inspection helps identify issues before they lead to failure. These checks should be part of standard gantry and bridge crane operating procedures.

Recommended Inspection Methods:

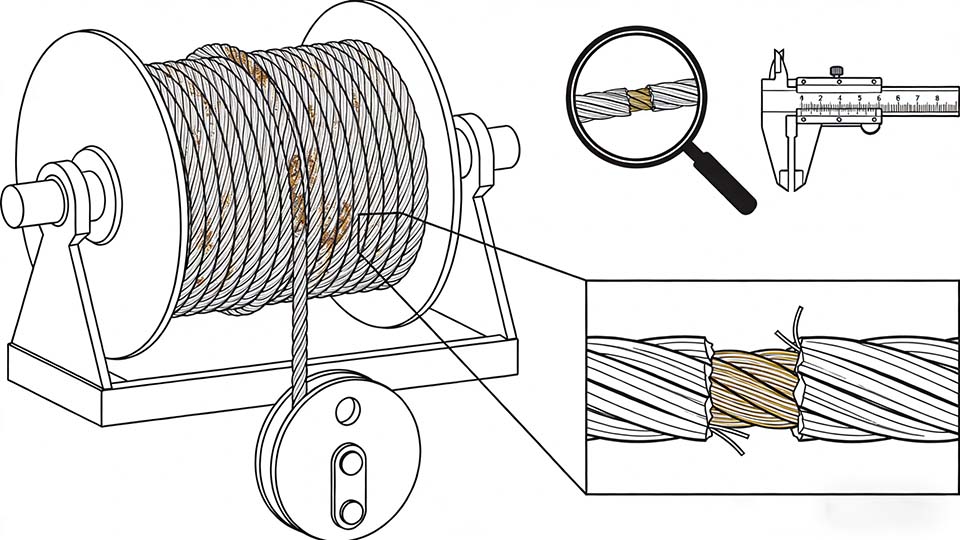

Visual Inspection: Make this a daily routine check. Watch for obvious wear—broken wires, rust, kinks, or bends.

Detailed Periodic Inspection: Have qualified staff do a more thorough check. They might use non-destructive testing (NDT) methods like magnetic particle or ultrasonic testing to find internal issues.

Maintenance Focus: Effective maintenance involves cleaning and lubrication. Correct installation is also critical; our guide on drawing crane wire rope winding paths can help prevent early wear.

Replacement should be based on the rope's condition, not a fixed timeline. Consider replacement when you observe:

Planning for replacement in advance helps avoid unplanned downtime.

The service life of a gantry crane wire rope depends on load conditions, environment and maintenance. Regular inspections are the best way to ensure safe operation, and rope replacement needs a factual assessment of wear and damage.

As a leading overhead crane manufacturer, we know these components thoroughly. For inspection guidance or equipment selection, contact our specialists.

TO TOP