WhatsApp: +8619037303916

Email: [email protected]

WhatsApp: +8619037303916

Email: [email protected]

In today's market, the vast array of electric hoists available can leave consumers bewildered. With a plethora of brands and a wide price range, selecting the right electric hoist for your needs often feels like navigating through a maze. This confusion is further compounded by the stark price differences among seemingly similar products. Why do some electric hoists come with a premium price tag while others are markedly cheaper? The answer often lies in the quality of components used in these hoists, which directly impacts their performance, safety, and longevity.

With this backdrop, our aim today is to demystify the components that make up high-quality electric hoists. By understanding what goes into the making of these essential industrial tools, you'll be better equipped to make informed decisions, ensuring you choose a product that not only meets your lifting needs but also offers the best value for your investment.

Before we begin, please allow me to show our kinocranes electric hoist products:

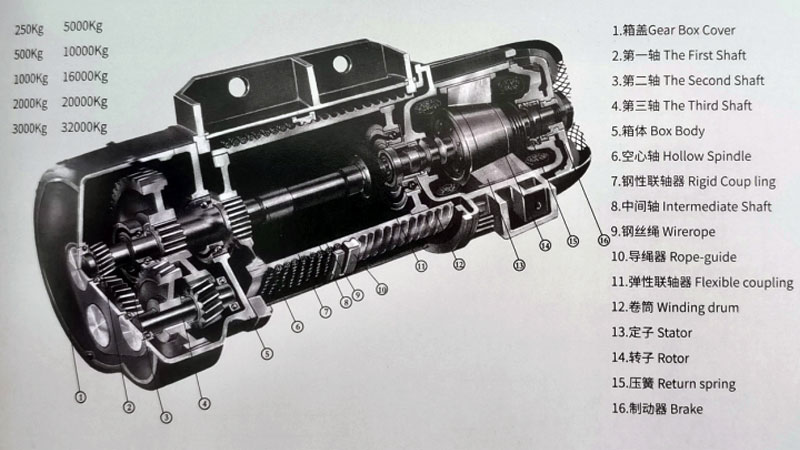

A Closer Look: The Anatomy of an Electric Wire Rope Hoist

Before we delve deeper into the core components that define a high-quality electric hoist, let's take a moment to examine the cross-sectional view of an electric wire rope hoist. Understanding its composition provides a more intuitive grasp of how these critical parts come together to ensure operational efficiency, safety, and reliability. This visual exploration will lay the groundwork for appreciating the significance of each component's quality as we proceed.

In the intricate world of electric hoists, understanding the anatomy through a cross-sectional view can significantly demystify its operation and design. Let's break down the components:

Understanding these components not only provides clarity on how electric hoists function but also highlights the importance of each part in ensuring efficient, safe, and reliable lifting operations.

Conical Brake Motors: The Heart of Electric Hoists

The Role and Importance

1. Conical brake motors are pivotal in the operation of electric hoists, providing the necessary power and control for lifting. The quality of these motors significantly influences the hoist's efficiency and safety.

In the design of conical brake motors, particularly those used in electric hoists, the stator coil height plays a crucial role in determining the motor's efficiency and performance. Taking a 7.5 kW motor as an example, we observe that the standard coil height we employ is 110 millimeters, compared to the more common heights of 95 millimeters and even 90 millimeters seen in other models. This comparison highlights a significant principle: the greater the height of the coil, the more copper wire it contains.

This increase in copper wire not only contributes to a larger torque but also results in a lower current requirement for the same power output. Essentially, by optimizing the stator coil height to 110 millimeters, we achieve a motor that is not only more powerful but also more efficient and economical in its operation. This design choice reflects our commitment to providing high-quality, high-performance electric hoists that meet our customers' demanding lifting needs.

2. Standard vs. High-Height Stator Coils

A key differentiator in motor quality is the height of the stator coils. Higher coil heights mean more copper wire, resulting in greater torque and reduced electrical consumption. This comparison sheds light on why some motors outperform others in terms of power efficiency and operational cost.

3. Rotor, Stator, and Bearings

The design and manufacturing quality of the rotor, stator, and shaft end bearings specifically tailored for lifting mechanisms also play a crucial role in ensuring smooth and reliable hoist operation.

Couplings: Ensuring Smooth Power Transmission

Types and Functions

Couplings are essential for transmitting power from the motor to the hoist mechanism. The choice between different types of couplings affects the hoist's vibration levels and operational smoothness.

Thicker Couplings for Enhanced Performance

Our analysis reveals that thicker couplings with larger outer diameters offer superior durability and performance, explaining the discrepancy in component quality among different brands.

When it comes to the couplings used in 5-ton electric hoists, we opt for a thicker design with an inner tooth outer diameter of 51.5 millimeters. In comparison, standard hoists typically feature couplings with an inner tooth outer diameter of 44 millimeters. By choosing a thicker coupling design, we enhance the strength and durability of the coupling, ensuring it can withstand the demanding loads and operating conditions associated with heavy lifting tasks. This strategic decision reflects our commitment to providing robust and reliable electric hoists that meet the highest standards of performance and safety.

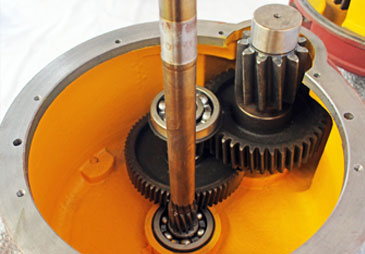

Gearboxes: Maximizing Efficiency and Lifespan

Quality Manufacturing Processes

The gearbox is another critical component where quality matters. High-quality gearboxes feature precision machining, superior materials, and advanced heat treatments, contributing to their reliability and noise reduction.

| Features | KINOCRANES High-Quality Gear | Standard-Quality Gear |

| Material | Made from high-quality 45# round steel from reputable large steel mills, uniform without pores or defects | Made from round steel from small mills, mixed internal composition, contains harmful elements |

| Processing Technique | Precision cutting, heating, forging, machining, gear rolling, high-frequency heat treatment, annealing, keyway milling, gear grinding | Substandard processing technique, low precision, lack of gear grinding |

| Heat Treatment Technique | Advanced high-frequency heat treatment, high-temperature annealing | Poor heat treatment resulting in inadequate hardness |

| Thickness | Thicker for increased overload capacity and lifespan | Thinner, reducing overall strength |

| Noise and Vibration | High transmission efficiency, low noise, minimal vibration | High noise and excessive vibration during operation |

| Toughness | Internal toughness to reduce tooth breakage and bending | Insufficient toughness leading to tooth breakage and bending |

| Meshing Clearance | High precision meshing accuracy | Excessive or insufficient meshing clearance |

| Features | Gearbox Casing (Body/Cover) |

| Material | Cast iron material processed into two parts: body and cover |

| Thickened Body | Thickened design for reduced noise and increased overall strength, minimizing the risk of body fracture or cover cracking |

| Advantages | Provides enhanced durability and noise reduction during gear transmission |

| Typical Thin Casing | Thin body and cover leading to higher noise levels during operation, prone to cracking and detachment during overload or impact, posing risks of accidents and injuries |

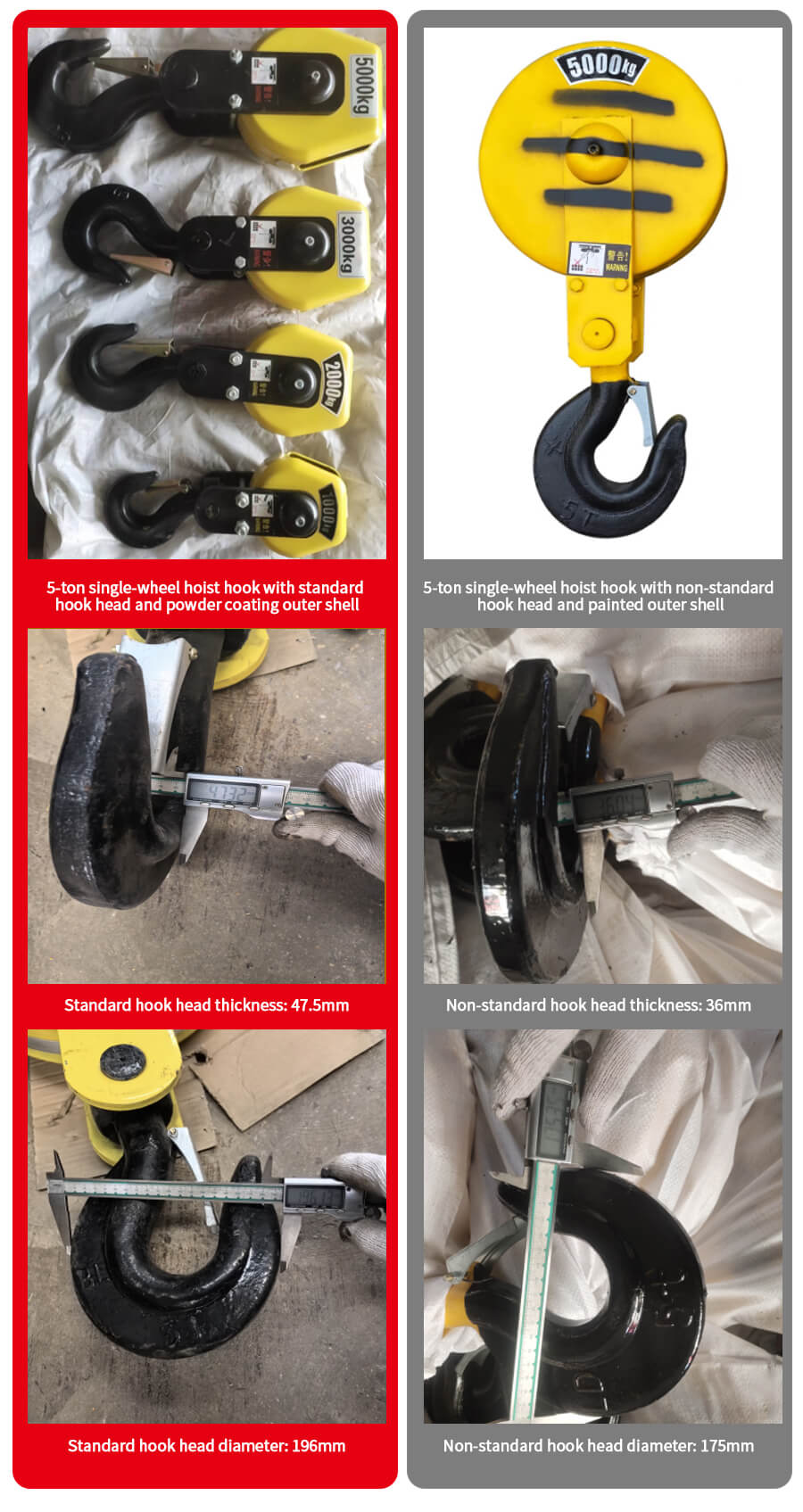

Hooks and Safety Devices: Critical for Operational Safety

Safety First

The design and material quality of hoist hooks and safety devices like limit switches and overload protectors are paramount. High-quality components ensure operational safety and extend the lifespan of electric hoists.

Electric Hoist Trolley

Electric hoist trolley is a motorized device that is used to move heavy loads along an overhead beam.

| Features | KINOCRANES Premium Configuration | Regular Configuration |

| Wall Panel Thickness | 20mm | 18mm |

| Gearbox Casing | Thicker casing | Thinner casing |

| Trolley Wheels Material | Forged 45# steel with carburizing treatment | - |

| Bearings | Model 6408, superior quality | Model 6408, standard quality |

| Axle | High-quality 45# steel, blueing treatment, anti-loosening pins | 20-45# steel, no anti-corrosion treatment, double thin nuts |

In conclusion, the diversity in electric hoist pricing can often be attributed to the quality of their components. Understanding these differences empowers you to make choices that prioritize safety, efficiency, and long-term savings. By selecting high-quality electric hoists, you invest in reliability and performance that stands the test of time.

TO TOP