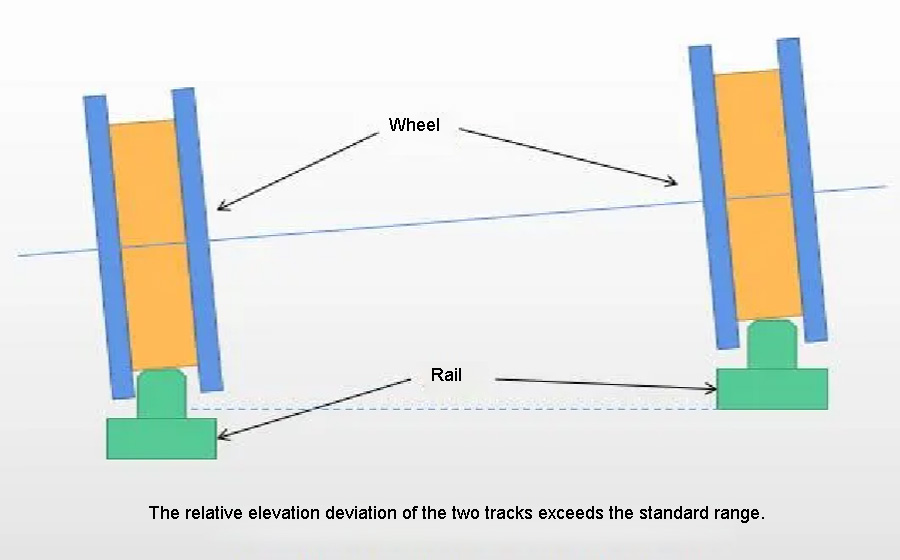

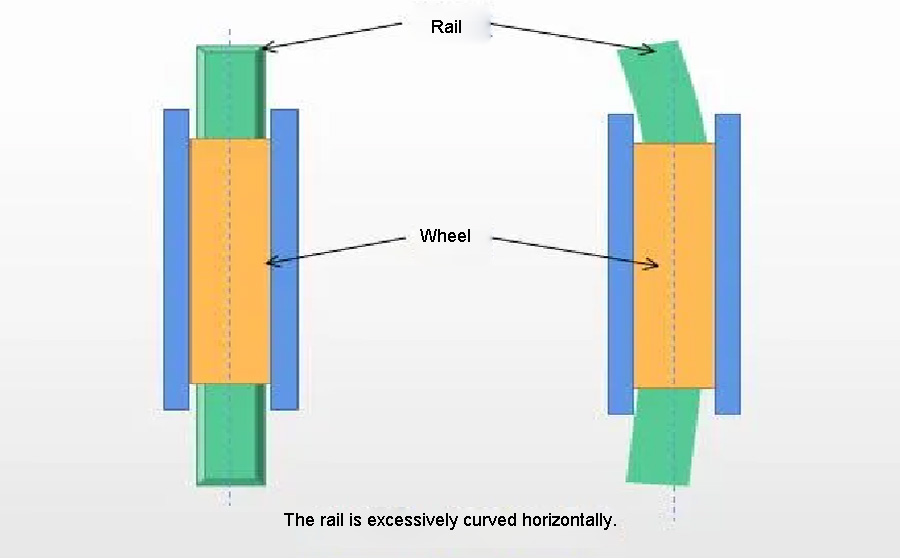

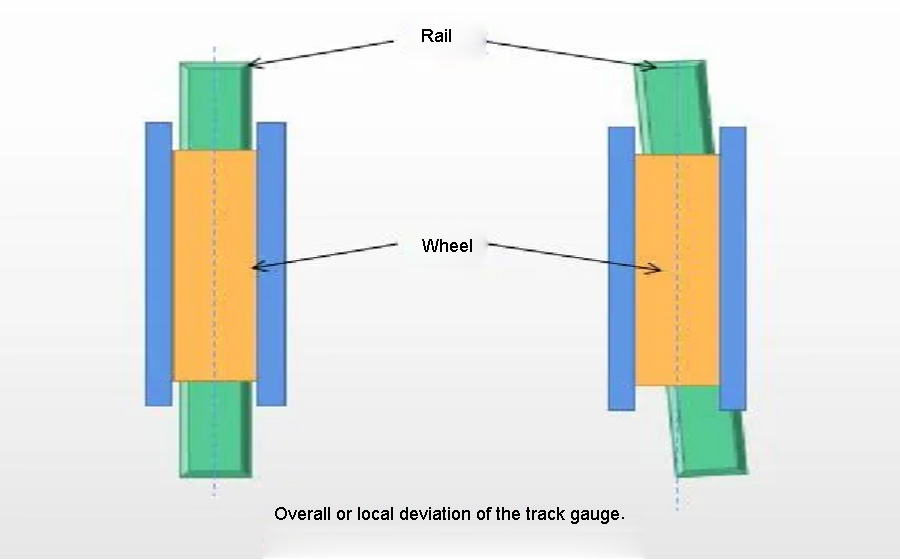

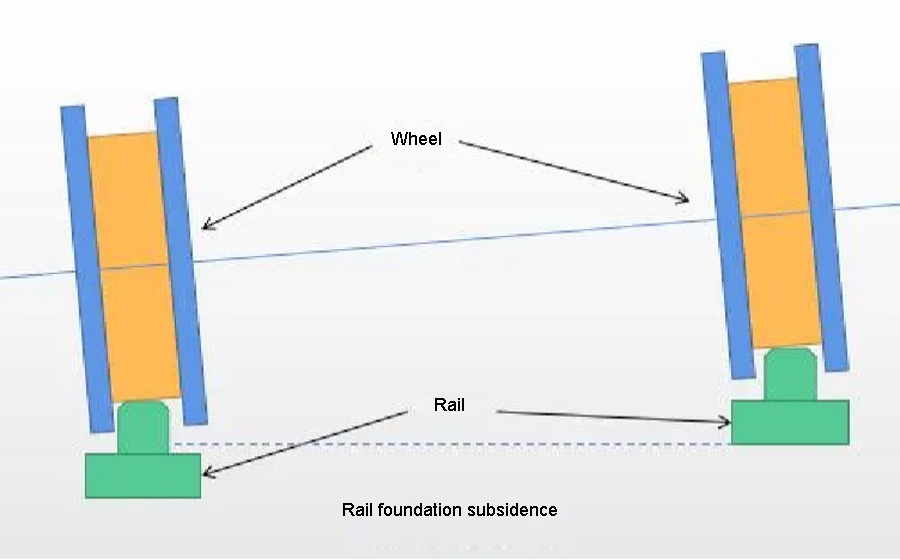

Is your overhead crane grinding itself to pieces? That screeching sound and sideways drift are signs of rail flange climbing—a costly safety hazard where wheels violently grind against rails.

This practical guide reveals 14 proven fixes to stop the damage. Learn how to protect your overhead crane from this destructive "rail gnawing" and keep your operations running safely.

Catch these symptoms before costly repairs:

Regular inspection of these 14 areas prevents 95% of rail gnawing issues. Consistent maintenance extends crane rail and wheel life while ensuring safe overhead crane operation.Need professional solutions? Our overhead crane series features robust designs that resist rail gnawing. Get a free assessment of your crane system →

TO TOP