When purchasing a crane, most buyers don’t simply compare prices or lifting capacities. If you have purchased or operated cranes before, you may already know that many problems only appear after the crane is put into service:

These issues often lead buyers to ask a critical question when purchasing again: How can I ensure the crane is truly reliable — not just on paper, but over its entire service life, The answer lies not only in design parameters, but more importantly in manufacturing quality and process control.

From real operating experience, industrial customers often want to avoid:

These risks are not accidental.

In most cases, they are directly related to how the crane is manufactured.

At Kinocranes, crane manufacturing is not just about production — it is about engineering discipline, safety assurance, and long-term reliability.

As cranes are safety-critical equipment operating in demanding industrial environments, manufacturing quality directly determines structural strength, fatigue life, and operational stability.

That is why Kinocranes integrates quality control, testing, and engineering standards into every stage of manufacturing.

A crane’s reliability is built long before it reaches the job site.

Poor manufacturing quality can lead to:

Kinocranes focuses on manufacturing consistency and process control to ensure every crane delivers stable performance throughout its service life.

Structural integrity is the foundation of crane safety.

Kinocranes applies controlled structural fabrication and welding processes to ensure:

Critical structural components are manufactured with strict welding procedures and inspection standards, minimizing internal stress and reducing the risk of long-term fatigue damage.

Customer value:

✔ Improved safety margin

✔ Longer structural service life

✔ Reliable performance in heavy-duty and high-frequency operations

Manufacturing accuracy directly affects crane operation smoothness and component wear.

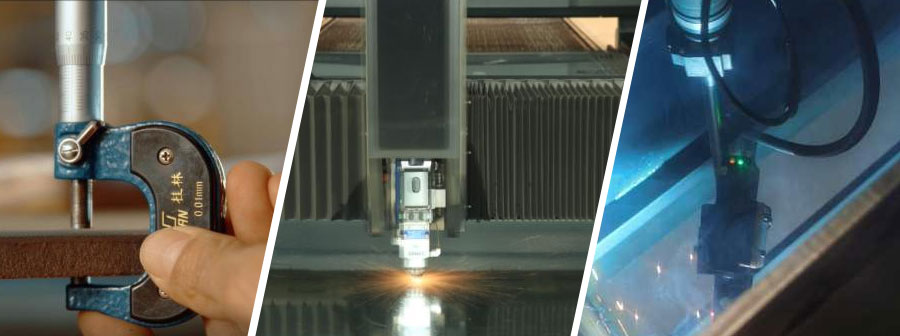

Through controlled machining and standardized assembly processes, Kinocranes ensures:

This focus on precision reduces unexpected wear, vibration, and adjustment issues during operation.

Customer value:

✔ Lower maintenance frequency

✔ Improved operational stability

✔ Reduced lifecycle cost

Testing is not optional — it is essential.

Kinocranes integrates inspection and testing throughout the manufacturing process, including:

These procedures verify not only compliance with standards, but also real-world performance under operating conditions.

Customer value:

✔ Verified safety and compliance

✔ Reduced commissioning risk

✔ Higher confidence in long-term operation

For buyers who require deeper technical understanding, Kinocranes provides detailed manufacturing and quality control documentation. These documents outline key manufacturing processes, inspection standards, and testing procedures used to ensure consistent crane quality.

For cranes operating in ports, steel plants, or outdoor environments, corrosion protection is critical.

Kinocranes applies controlled surface treatment and coating systems to:

Customer value:

✔ Longer service life

✔ Reduced repainting and maintenance

✔ Better protection in aggressive environments

Kinocranes’ manufacturing process is designed with one clear goal:

to reduce customer risk while ensuring reliable, long-term performance.

By focusing on:

We deliver cranes that are safer, more durable, and better suited for demanding industrial applications.

These manufacturing principles are applied across Kinocranes’ crane product portfolio, including overhead cranes, gantry cranes, and customized industrial lifting solutions.

You can explore specific crane models and technical specifications here:

Manufacturing quality is not a slogan at Kinocranes.

It is a system built on engineering standards, controlled processes, and responsibility for every crane we deliver.

Understanding how cranes are manufactured helps buyers make more informed decisions. If you are evaluating cranes for a specific application or project, reviewing both manufacturing quality and real operating requirements is essential. Contact us.

TO TOP