Crane inverter is critical to both the efficiency and safety of crane operation. As a core piece of crane components, the crane frequency converter precisely regulates motor speed and enables smooth crane operation overall. Yet inadequate operation or neglect of regular maintenance can easily lead to equipment failure and even create safety hazards.

This guide sets out a clear maintenance manual and defines key safe operating steps, helping to extend the service life of the crane inverter and keep it running at optimal performance.

Familiarize yourself with the crane inverter’s components and operating principles before use. Always follow the manufacturer’s instructions strictly.

Choose a crane frequency converter that matches the motor’s rated power and operational requirements. Confirm its compatibility with the power supply’s voltage and frequency.

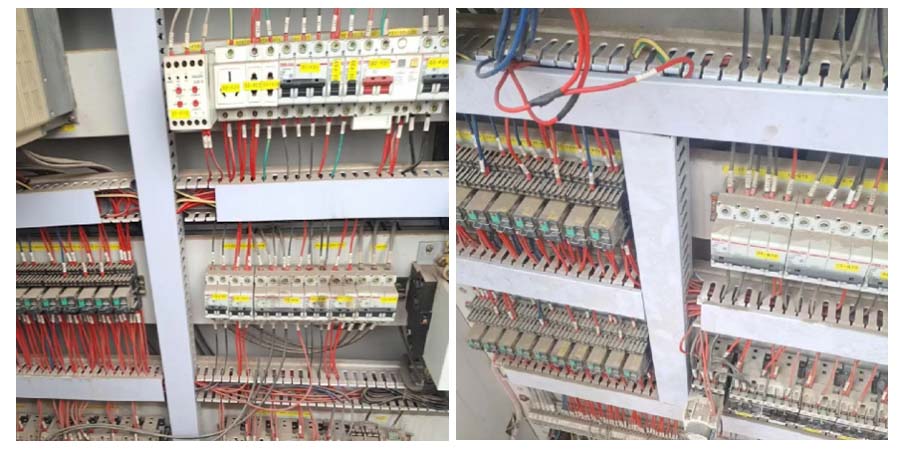

Use double-insulated cables and follow standard wiring diagrams. Opt for reliable terminal boxes and cable trays for easier maintenance and better safety.

When the crane inverter is in operation, beef up equipment protection–focus on warding off water ingress, dust contamination and other external environmental impacts. Also, prevent circuit short circuits and overcurrent faults during operation.

Perform regular maintenance and inspections on the crane inverter, and identify and address any problems promptly.

Due to harsh working environments, dust and debris can accumulate inside the crane inverter. Clean it periodically to avoid overheating and electrical faults.

Inspect connections and components routinely to prevent unexpected breakdowns.

The heat sink dissipates internal heat. Keep it free from blockages and ensure proper ventilation for efficient crane inverter operation.

The power unit and fan are critical for temperature control. Check their performance regularly to avoid overheating.

During maintenance, adhere to safety protocols and standardized workflows. Prioritize safety in every step.

Crane inverters are key to safe and efficient crane operation. Stick to proper operation and regular maintenance, and the crane inverter will run reliably – this also makes sure the cranes it controls work smoothly.

If you need more professional support or high quality crane components, please contact us immediately.

TO TOP